-

tel:

+86 15995930942 -

email:

gs@guoshengchina.cn

GS-V352 Three System 14G Computerized Flat Shoe Upper Knitting Machine

Type:flyknit uppers knitting machine

Production Capacity:100%

Knitting Style:Warp

Knitting Method:computerized flat knitting machine for shoes upper

Computerized:Yes

Gauge:14 GG

Knitting width:36 inch

The three system small head cooperates with the head servo to rotate at

high speed,with a maximum response of 0.05 seconds Greatly improve textile efficiency and better stability.

Many kinds of machine's width are suitable for single.double or piece by

piece shoes upper knitting.

|

MODEL |

V352 |

|

GAUGE |

14G |

|

KNITTING SYSTEM |

THREE SYSTEM SINGLE CARRIAGE |

|

KNITTING WIDTH |

52(INCH) |

|

KNITTING SPEED |

MAX.1.2M/SEC |

|

KNITTING FUNCTION |

TRANFER、TUCK、MISS、JACQUARD、INTARSIA、HIDE OR APPARENT SHAPING. |

|

STITCH DENSITY |

STITCH SYSTEM CONTROLLED BY STEPPING MOTOR,32 SECTION STITCH |

|

RACKING |

CONTROLLED BY AC SERVO MOTOR,RACKING WITHIN 2 INCHES |

|

DRIVE SYSTEM |

SYNCHRONOUS BELT DRIVE,AC SERVO SYSTEM |

|

NEEDLE SELECTION |

CONTROLLED BY COMPUTER,ELECTRIC MAGNET NEEDLE CHOOSE SYSTEM |

|

YARN CARRIER |

2x8YARN CARRIERS ON EACH SIDE OF 4 GUIDE RAILS,SHIFTABLE ON ANY NEEDLE POSITION |

|

TAKE DOWN ROLLER |

PROGRAMMED INSTRUCTION CONTROLLED BY STEPPING MOTOR, |

|

SINKER SYSTEM |

ASSIST KNITTING,HAVE VARIOUS RESULTS OF SHAPING AND STOP. |

|

PROTECTION SYSTEM |

THE MACHINE WILL AUTOMATICALLY ALARM IF YARN BREAKING,FLOAT YARN,REWIND, |

|

CONTROL SYSTEM |

1、ADOPT LCD SCREEN,INPUT DEVICE:USB,SYSTEM MEMORY 1G, |

|

POWER |

220V ,SINGLE-PHASE,HAVE MEMORIZING FUNCTION AT THE POWER-OFF MOMENT |

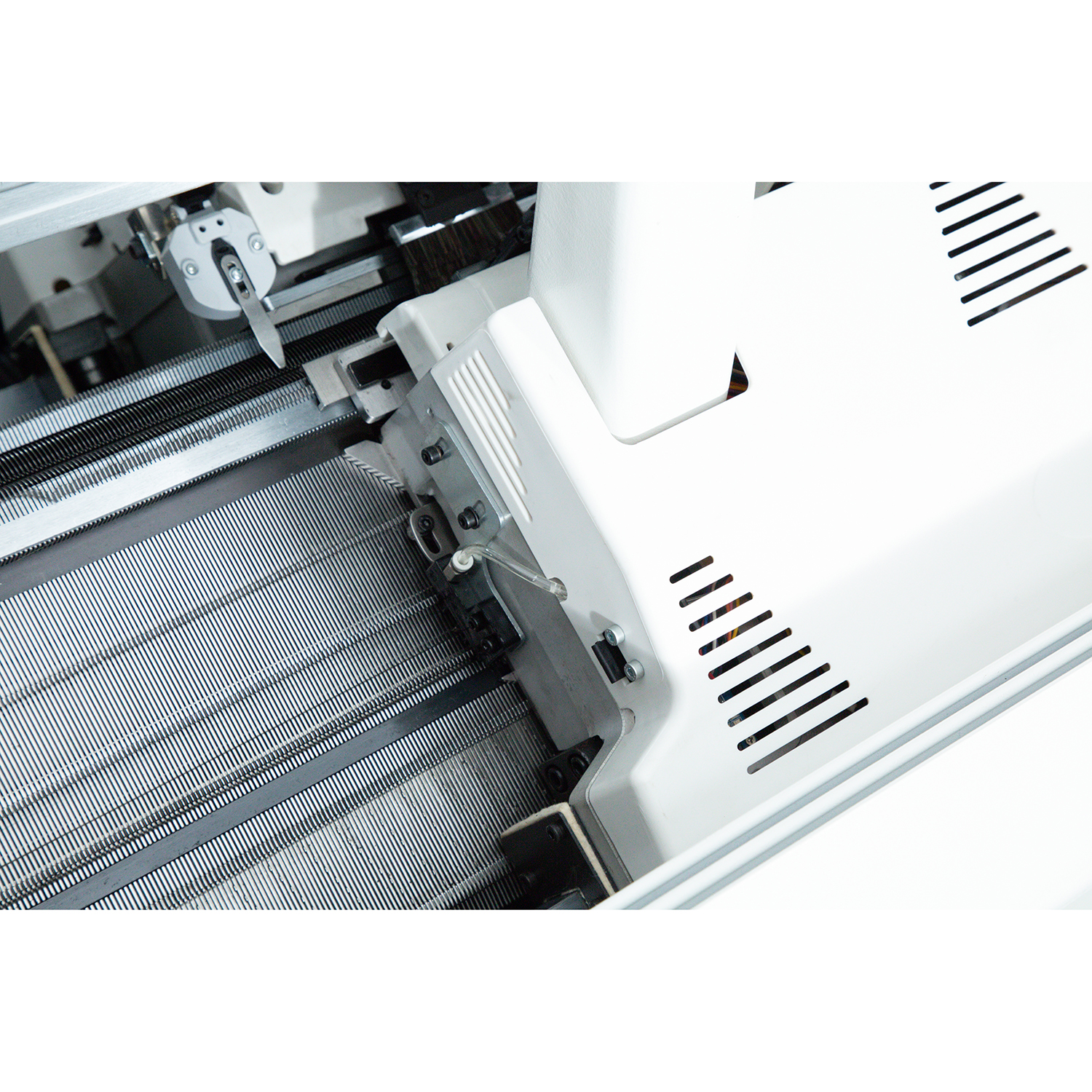

Needle bed:

Divided structure ,steel sheet made from import high quality steel precisely punched and fine polished to reduce the resistance with needles and increase the longevity.

Touch screen:

One-touch screen,easy operation ,satisfy experience .The display is capable of showing pictures with colors,displaying number og pieces,finished pieces,knitting time,speed,roller,mesh numbers ,yarn nozzle,etc.,which can be adjusted any time during the operation of the machine .

Positive yarn provider :

Positive yarn providing ,successfully reduce yarn resistance ,increase knitting efficiency.

Carriage:

The journey of the carriage can be automatically adjusted as per the width of the knitting fabric.The adjustment can be done swiftly and the positioning is precise,which avoids the useless movement and greatly elevates the productivity of the machine.

Yarn storage:

The yarn storage is installed between the yarn bucket and knittting system ,which greatly improves the uneven tension caused by overlong yarn journey ,reduces the resistance of the running yarn ,resulting in elevated texture of the fabrics and capable of controlling the density and dimension of the fabrics.

Q:Supplier profile

A:We’re the manufacturer of flat knitting machine since 1992,with more than 100 technicians in after-sale service team,have served

customers in more than 40 countries.

Q:Product introduction

A:The machine is suitable for collar,sweater,shoe upper,hat,scarf,rib...textile production.Just design pattern by software in the

computer,and input pattern to machine by USB,you can knit anything you need.

Q:Machine warranty

A:One year.For any spare part,the customer can purchase from us for life.

Q:Delivery time

A:Normally 15 days after deposit.If the machine you need is in stock,we can ship it shortly.

Q:Machine package

A:The inner layer is plastic packaging to avoid dust;the middle layer is vacuum packaging to avoid moisture and rust during sea

shipping;outside is wooden package and iron under frame to protect machine during transportation.

Q:More question

A:Please feel free to contact Summer via +86 15995930942 or summer@guoshengchina.cn