-

tel:

+86 15995930942 -

email:

gs@guoshengchina.cn

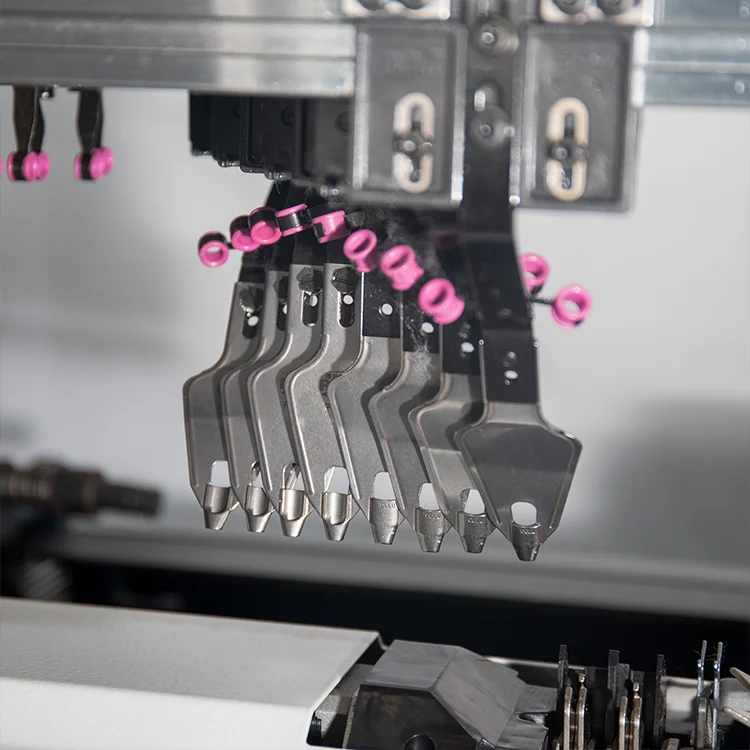

GS-SZ352 Full Computerized Professional Fashion Sweater Jacquard Flat Knitting Machine

The fast cornering of carriage. Superior servo drive assembly makes the fast cornering of carriage came true, improved

the efficiency of knitting more than 10%.

Well-designed angle of needle bed tooth mouth to ensure rapid antonomous falling of fabrics.

Duplex table technique of thick needle, fulfilling double distance and expanding table scope significantly.

Triangle baseboard, adopting precise forging materials with the most superior quality, some are produced by Taiwanmanufacturer according to our brand new design program with optimized degree of surface pressure, making surfaceof fabrics more even, density more proper and knitting more smooth.

|

MODEL |

GS-SZ352 |

|

GAUGE |

3-5-7G,5G,6G,7G,8G,9G,10G,12G,13G,14G,15G,16G |

|

KNITTING SYSTEM |

THREE SYSTEM SINGLE CARRIAGE |

|

KNITTING WIDTH |

52(INCH) |

|

KNITTING SPEED |

MAX.1.4M/SEC |

|

KNITTING FUNCTION |

TRANFER、TUCK、MISS、JACQUARD、INTARSIA、HIDE OR APPARENT SHAPING. |

|

STITCH DENSITY |

STITCH SYSTEM CONTROLLED BY STEPPING MOTOR,128 SECTION STITCH SELECTABLE, ADJUSTABLE SCOPE SUPPORTED BY SUBDIVISION TECHNOLOGY:0-650 |

|

RACKING |

CONTROLLED BY AC SERVO MOTOR,RACKING WITHIN 2 INCHES AND WITH FINE ADJUSTIING FUNCTION. |

|

DRIVE SYSTEM |

SYNCHRONOUS BELT DRIVE,AC SERVO SYSTEM |

|

NEEDLE SELECTION |

CONTROLLED BY COMPUTER,ELECTRIC MAGNET NEEDLE CHOOSE SYSTEM WITH HIGH EFFICIENCY. |

|

COMB DEVICE |

NO WASTE YARN COMB,WITOUT WASTE YARN,DIRECTLY LIFTING THE COMB SAVES TIME FOR KNITTING WASTE YARN. WHEN COMBINED WITH SCISSORS AND CLIPS,SINGLE PIECES CAN BE DROPPED WITHOUT THE NEED FOR WASTE YARN, HELPING WORKERS TO SAVE TIME AND SAVING YARN COST. |

|

SCISSOR AND CLAMP |

INCLUDING 2 SCISSOR AND 4 CLAMPS ,WHICH INDIVIDUALLY CONTROLLED BY 6 MOTORS SEPARATELY, LOCATED THE BOTH OF NEEDLE BED SEPARATELY,FURTHER TO INCREASE THE WORK EFFICIENCY AND TO REDUCE YARN CONSUMPTION. |

|

YARN CARRIER |

2x8YARN CARRIERS ON EACH SIDE OF 4 GUIDE RAILS,SHIFTABLE ON ANY NEEDLE POSITION |

|

NO WASTE YARN COMB |

NO WASTE YARN COMB,WITOUT WASTE YARN,DIRECTLY LIFTING THE COMB SAVES TIME FOR KNITTING WASTE YARN. WHEN COMBINED WITH SCISSORS AND CLIPS,SINGLE PIECES CAN BE DROPPED WITHOUT THE NEED FOR WASTE YARN, HELPING WORKERS TO SAVE TIME AND SAVING YARN COST. |

|

TAKE DOWN ROLLER |

PROGRAMMED INSTRUCTION CONTROLLED BY STEPPING MOTOR,128 SECTION LEVELS SELECTION ADJUSTABLE AREA:0-100 |

|

SINKER SYSTEM |

ASSIST KNITTING,HAVE VARIOUS RESULTS OF SHAPING AND STOP. |

|

PROTECTION SYSTEM |

THE MACHINE WILL AUTOMATICALLY ALARM IF YARN BREAKING,FLOAT YARN,REWIND,END OF KNITTING, FAIL OF RACKING,NEEDLE BREAKAGE,SAFETY SENSOR AND ERROR PROGRAMMING OCCUR ECT. |

|

CONTROL SYSTEM |

1、ADOPT LCD SCREEN,INPUT DEVICE:USB,SYSTEM MEMORY 256MB,A GREAT AMOUNT OF DESIGN FILES CAN BE STORED. 2、MONITORING MENU,EACH KIND OF OPERATING PARAMETER,CAN BE SHOWN, AND THEY CAN BE ADJUSTED AT ANY TIME WHEN THE MACHINE IS RUNNING. 3、DESIGN SYSTEM IS VISUAL AND EASY TO UNDERSTAND AND UPGRAD. 4、MULTI LANGUAGE VERSION,THERE ARE CHINESE,ENGLISH ETC. |

|

POWER |

220V ,SINGLE-PHASE,HAVE MEMORIZING FUNCTION AT THE POWER-OFF MOMENT |

Q:Supplier profile

A:We’re the manufacturer of flat knitting machine since 1992,with more than 100 technicians in after-sale service team,have served

customers in more than 40 countries.

Q:Product introduction

A:The machine is suitable for collar,sweater,shoe upper,hat,scarf,rib...textile production.Just design pattern by software in the

computer,and input pattern to machine by USB,you can knit anything you need.

Q:Machine warranty

A:One year.For any spare part,the customer can purchase from us for life.

Q:Delivery time

A:Normally 15 days after deposit.If the machine you need is in stock,we can ship it shortly.

Q:Machine package

A:The inner layer is plastic packaging to avoid dust;the middle layer is vacuum packaging to avoid moisture and rust during sea

shipping;outside is wooden package and iron under frame to protect machine during transportation.

Q:More question

A:Please feel free to contact Summer via +86 15995930942 or summer@guoshengchina.cn